Borescope Inspection Testing Services

Borescope Inspection Testing Services Specification

- Display Type

- LCD Monitor or Mobile Device

- Operating Temperature

- -20°C to +60°C

- Light Source

- LED, Adjustable Brightness

- Data Output

- USB/SD Card Storage

- Image/Video Capture

- Available

- Probe Diameter

- 4mm to 8mm

- Probe Length

- 1m to 5m

- Camera Resolution

- Up to 1080p HD

- Industry Served

- Aerospace, Automotive, Power Generation, Oil & Gas, Manufacturing

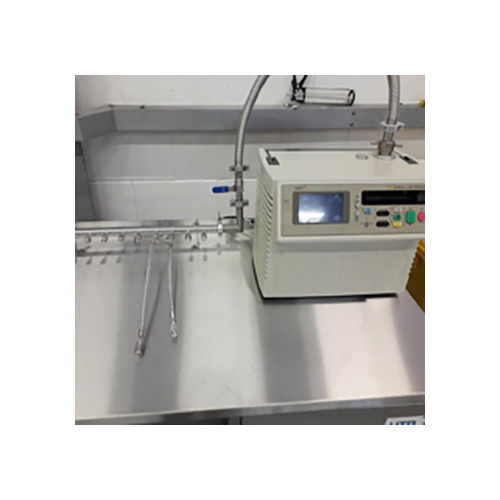

About Borescope Inspection Testing Services

Borescope Inspection

A borescope is an optical device comprising a rigid or flexible tube with an eyepiece on one end and an objective lens on the other, connected by a relay optical system. Some models include optical fibers for illumination in hard-to-reach areas.

Applications:

- Aerospace: Inspection of aircraft engines, gas turbines, and steam turbines for maintenance and safety.

- Automotive: Visual inspection of diesel engines, truck engines, and machined parts for burrs or surface finish.

- Industrial: Used in law enforcement, building inspection, and gun-smithing to inspect firearm bores.

Borescope inspection helps identify issues early, minimizing unnecessary maintenance and reducing costs, particularly in large turbines.

Advanced Visual Diagnostics

Borescope inspections deliver high-definition imagery, enabling effective detection of faults and anomalies within machinery and infrastructure. The flexibility in probe size and length allows for precise analysis in restricted or deep-set locations, supporting maintenance and safety protocols.

Versatility Across Industries

Our service is trusted by aerospace, automotive, power generation, oil & gas, and manufacturing industries. The adaptability of our borescopes ensures optimal results in diverse operating conditions, from -20C to +60C, supporting both routine and emergency inspections.

FAQs of Borescope Inspection Testing Services:

Q: How is a borescope inspection performed using your services?

A: A trained technician inserts a borescope probe, with a diameter of 4mm to 8mm and length up to 5m, into the target area. The built-in camera transmits live HD images or video to an LCD monitor or mobile device, enabling thorough visual assessment and identification of issues.Q: What are the benefits of using high-resolution (1080p HD) borescopes?

A: High-resolution imaging allows clear visualization of even minor defects, facilitating accurate detection and documentation. This enhances maintenance planning and reduces downtime by addressing concerns before major failures occur.Q: When should borescope inspection testing be scheduled for industrial equipment?

A: Borescope inspections can be performed during routine preventive maintenance, when anomalies are suspected, or before major overhauls to assess internal conditions. Timely inspections help prevent unexpected breakdowns and maintain optimal asset performance.Q: Where can borescope inspection services be effectively applied?

A: Our services are ideal for inspecting turbines, engines, pipes, heat exchangers, and inaccessible equipment in aerospace, automotive, power generation, oil & gas, and manufacturing sectors throughout India.Q: What is the process for capturing and storing inspection data?

A: Images and videos of the inspection are captured in real-time and stored on USB drives or SD cards. This data can be used for further analysis, reporting, and maintenance records, ensuring traceability and informed decision-making.Q: How does adjustable LED brightness improve inspection quality?

A: The adjustable LED light source allows technicians to optimize illumination based on the inspection environment, revealing hidden defects and improving image clarity, especially in dim or reflective areas.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese