Ferrite Testing Services

Ferrite Testing Services Specification

- Application

- Industrial

- Testing Method

- Magnetic Induction, Metallographic

- Product Name

- Ferrite Testing Services

- Testing Type

- Ferrite Content Test

- Location

- India

- Service Type

- Laboratory Testing

- Report Delivery

- Digital & Hard Copy

- Sample Type

- Welds, Stainless Steel Components, Pressure Vessels

- Result Accuracy

- High Precision

- Service Mode

- Offline

About Ferrite Testing Services

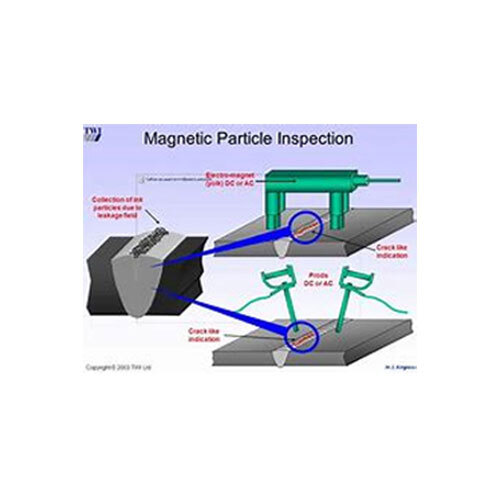

Ferrite Content Analysis is a Non-Destructive Testing (NDT) method that provides crucial data for assessing austenitic stainless steel and duplex materials.

Purpose and Benefits:

The delta ferrite percentage or Ferrite Number (FN) allows for a technical evaluation of:

- Corrosion susceptibility

- Mechanical properties

- Service suitability and reliability

Testing Requirements:

- Proper ferrite testing requires both a minimum material thickness and a minimum specimen size.

- Test results are interpreted following current specifications and/or customer requirements.

- Reports may include drawings to indicate tested locations when necessary.

Applications:

Ferrite Testing applies to inspecting:

- Austenitic stainless steel and duplex stainless steels

- Welds (including tubing)

- Normal construction steel with austenitic chrome alloy steel welded cladding (e.g., boilers, vessels)

- Weldments, castings, forgings, weld overlays, and wrought materials

- Butt/fillet welds

- Stainless weld overlays on non-ferrous interfaces

- In-service and in-construction components

Advantages:

- Fast and accurate analysis

- Utilizes highly portable digital technology

- Offers variable calibration in both Ferrite Number (FN) and % Ferrite using AWS Standards

- Testing instruments comply with ANSI/AWS A4.2 and DIN EN ISO 8249 standards

- Calibration is traceable to internationally approved IIW secondary calibration standards

Limitations:

- Not suitable for materials above 125 deg F

- Surface preparation is critical for accurate results

- Requires both a minimum material thickness and specimen size

- The specimen's shape may affect results; correction calculations may be possible in some cases

Ferrite Content Analysis is a vital tool for ensuring material integrity, particularly in industries reliant on corrosion resistance, mechanical strength, and long-term service reliability.

Unmatched Precision and Reliability

Our Ferrite Testing Services utilize state-of-the-art Magnetic Induction and Metallographic techniques for evaluating welds, stainless steel parts, and pressure vessels. This ensures exceptional precision in ferrite content measurement, helping industries maintain stringent quality standards. Each test is performed in a controlled lab environment by trained professionals, minimizing error and maximizing reliability.

Comprehensive Reporting Options

Clients receive test results in both digital and hard copy formats for ease of reference and compliance purposes. Our comprehensive reports detail findings and measurement methods, making it simpler to document quality and satisfy inspection requirements for industrial audits.

Serving India's Industrial Sector

Catering exclusively to the Indian market, our offline services are designed around the needs of local industries. We support plant operators, fabricators, and maintenance teams in achieving compliance, sustaining performance, and ensuring safety in pressure-retaining structures and process equipment.

FAQ's of Ferrite Testing Services:

Q: How is ferrite content tested in your laboratory services?

A: We employ both Magnetic Induction and Metallographic techniques to analyze ferrite content in welds, stainless steel components, and pressure vessels. These methods provide high accuracy and reliability in measuring ferrite phases, ensuring optimal structural integrity.Q: What sample types are suitable for your Ferrite Testing Services?

A: Our laboratory can test a range of samples, including welds, stainless steel components, and pressure vessels commonly found in industrial applications. These sample types ensure broad compatibility with various fabrication and maintenance needs.Q: When should industries consider conducting ferrite testing on their equipment?

A: Ferrite testing is crucial during and after fabrication, repair, or maintenance of stainless steel structures. It is particularly important before equipment enters service to confirm it meets the required safety and quality standards.Q: Where are your ferrite testing services available?

A: Our services are available throughout India. All samples are processed offline in our specialized laboratory, ensuring controlled conditions and high accuracy for all industrial clients in the region.Q: What is the process for submitting samples and receiving reports?

A: Clients provide sample materials for laboratory analysis. After testing, we deliver comprehensive results in both digital and hard copy formats, including detailed measurements and interpretations suitable for audits and compliance documentation.Q: How can industries benefit from ferrite content testing?

A: Ferrite testing helps detect improper ferrite content that could lead to cracking, corrosion, or premature failure in welds and components. Accurate results contribute to safer, more durable industrial equipment and easier regulatory compliance.Q: What level of result accuracy can clients expect from your services?

A: Our laboratory employs highly precise testing techniques, ensuring dependable and repeatable results. This accuracy underpins our reputation as a trusted service provider for critical industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese