Dye Penetrant Testing Services

Dye Penetrant Testing Services Specification

- Reporting Format

- Detailed Inspection Report with Photographic Evidence

- Technique

- Fluorescent/Solvent Removable Penetrant

- Inspection Method

- Visible & Fluorescent

- Application

- Surface Crack Detection

- Material Tested

- Metals, Welds, Components

- Service Mode

- Offline

- Testing Availability

- 24/7 as per client need

- Service Type

- Dye Penetrant Testing Services

- Penetrant Sensitivity Level

- Level 2 (General Industrial)

- Industry Served

- Aerospace, Automobile, Manufacturing

- Minimum Order Quantity

- As per requirement

- Test Type

- Non Destructive Testing (NDT)

- Standard Complied

- ASME, ASTM E1417

- Location Served

- On-Site

- Detection Level

- Detects surface-breaking defects

About Dye Penetrant Testing Services

Dye Penetrant Inspection (DPI)

Dye Penetrant Inspection (DPI), also known as Liquid Penetrant Inspection (LPI) or Penetrant Testing (PT), is a widely used and cost-effective method for detecting surface-breaking defects in non-porous materials such as metals, plastics, and ceramics.

Key Features and Applications

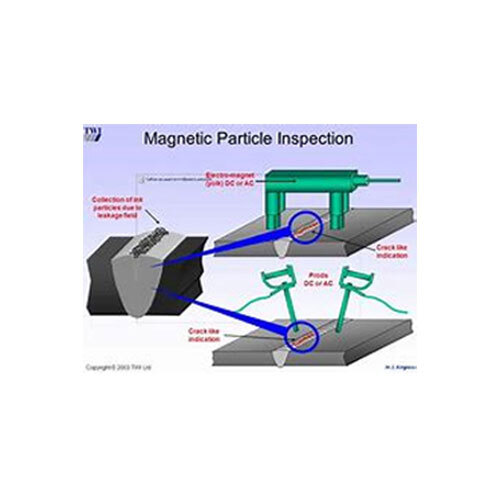

DPI is suitable for both non-ferrous and ferrous materials. However, for ferrous components, Magnetic Particle Inspection (MPI) is often preferred due to its ability to detect subsurface defects.

DPI is commonly used to identify defects in castings, forgings, and welded components. It effectively reveals issues such as:

- Hairline cracks

- Surface porosity

- Leaks in new products

- Fatigue cracks in in-service components

- Inspection Process

Surface Preparation:

The component surface must be thoroughly cleaned to remove any contaminants such as dirt, paint, oil, grease, or loose scale. These substances could either block the penetrant from entering defects or create false indications.

- Cleaning methods may include:

- Solvent cleaning

- Alkaline cleaning

- Vapor degreasing

- Metal blasting

Post-Blasting Treatment (if applicable):

If metal blasting is performed, it may mask small discontinuities by "working over" the defects. In such cases, a follow-up etching bath is recommended to reopen the discontinuities for effective inspection.

Benefits of DPI:

- Cost-effective and easy to perform

- Suitable for a wide range of materials

- Highly effective for detecting surface-breaking flaws

- Ideal for both new product inspection and in-service maintenance

By following proper cleaning procedures and preparation steps, Dye Penetrant Inspection ensures accurate and reliable detection of surface defects, enhancing the safety and quality of critical components.

Comprehensive Surface Defect Detection

Our testing services excel at identifying surface-breaking flaws in critical metal structures and components. Using Level 2 (general industrial) penetrant sensitivity, both visible and fluorescent techniques are applied to ensure accurate defect detection while preserving the integrity of the tested item. This approach is suitable for routine inspections or critical failure analysis across multiple sectors.

Expertise Across Key Industries

Serving the aerospace, automobile, and manufacturing industries, our experienced professionals adapt testing protocols to meet stringent safety and quality guidelines. We comply with internationally recognized standards (ASME, ASTM E1417) to provide stakeholders assurance in the safety and longevity of their products. Our NDT methods minimize downtime and support ongoing production requirements.

Detailed Reporting and Photographic Documentation

Clients receive in-depth inspection reports that are enhanced with photographic evidence of findings, helping decision-makers visualize the condition and pinpoint exact locations of detected flaws. These comprehensive documents assist in making informed maintenance or repair decisions, further supporting regulatory compliance and operational safety.

FAQ's of Dye Penetrant Testing Services:

Q: How does dye penetrant testing identify surface-breaking defects?

A: Dye penetrant testing works by applying a visible or fluorescent dye solution to the surface of the component. The solution seeps into any surface-breaking cracks or defects. After a developer is applied, any trapped dye emerges, making even the smallest flaws visible under suitable lighting or UV inspection, allowing for accurate detection of cracks.Q: What types of materials and components can be tested with this service?

A: Our services are designed for metals, welds, and various industrial components. This includes parts widely used in aerospace, automobile, and manufacturing industries, ensuring versatility and broad applicability.Q: When are your dye penetrant testing services available?

A: We offer dye penetrant testing 24/7, tailored to your schedule and operational requirements. This around-the-clock flexibility ensures minimal disruption to production or maintenance activities.Q: Where are the testing services conducted?

A: Testing is performed on-site across locations in India. Our team brings the necessary equipment directly to your facility, delivering convenience and reducing equipment transport risks.Q: What is the process involved in dye penetrant testing?

A: The process involves surface cleaning, application of penetrant, removal of excess dye, application of a developer, and then inspection using visible light or UV (for fluorescent testing). The entire method is non-destructive, allowing components to remain intact and in service.Q: How does your reporting format benefit clients?

A: We provide detailed inspection reports complete with photographic evidence. This visual documentation helps clients clearly understand findings, improve maintenance planning, and meet quality assurance requirements.Q: What standards and regulations do your services comply with?

A: Our dye penetrant testing strictly adheres to ASME and ASTM E1417 standards, reflecting the highest level of technical competence and compliance for surface flaw detection in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese