Metallography Testing Services

Metallography Testing Services Specification

- Type of Testing

- Metallography Testing Services

- Report Type

- Detailed Microstructure Analysis Report

- Specimen Type

- Metals and Alloys

- Analysis Tools

- Optical Microscope, Image Analysis Software

- Service Location

- All Over India

- Turnaround Time

- Fast and Reliable - Within 1 Week

- Testing Method

- Microstructural Examination, Grain Size Measurement, Inclusion Rating

- Service Provided By

- Skilled Technicians and Experienced Metallurgists

- Service Mode

- Offline

- Service Duration

- 1 Week

- Application

- Quality Control, Failure Analysis, Research & Development

- Sample Preparation

- Precision Cutting, Mounting, Polishing and Etching

- Testing Standards

- ASTM, IS, ISO

- Documentation

- Photomicrographs, Interpretation and Recommendations

About Metallography Testing Services

Material Characterization and Microstructure Analysis

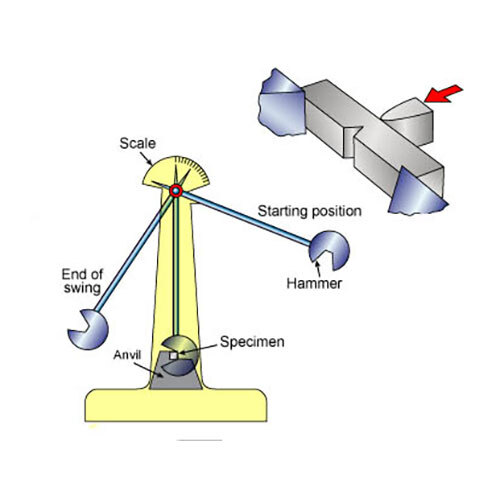

Material characterization through microstructure analysis is essential for evaluating properties like strength, corrosion resistance, and stability. The microstructure reveals the grain structure of materials in various conditions such as cast, wrought, heat-treated, or specially treated (e.g., carburizing, hardening).

This analysis also detects the presence of carbides, particularly chromium carbide, which is crucial in high chromium and nickel alloys.

Microstructure Analysis Tests Include:

- Micro Examination with Photographs

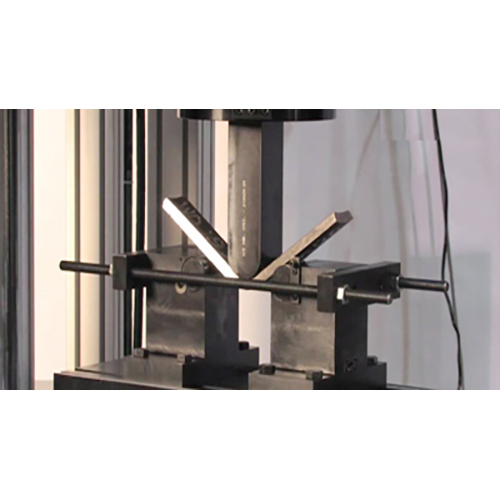

- Micro Examination for Welded Pipes

- Macro Examination for Forgings, Mock-ups, Fillet Welds, and Grain Flow

- Macro Examination for Pipes

- Weld Penetration Test with Measurements and Photographs

- SEM Test (Scanning Electron Microscope)

- Grain Stabilizing Test

- Carbide Morphology Analysis

- Porosity Evaluation Using Microscopic Methods

These tests provide vital insights into material quality, ensuring compliance with industry standards and performance requirements.

Comprehensive Microstructural Analysis

Our metallography testing covers critical aspects such as grain size measurement, inclusion rating, and microstructural examination of metals and alloys. By employing advanced methodologies, we ensure rigorous assessment that supports quality control, failure analysis, and research initiatives.

Expertly Prepared and Analyzed Samples

Each sample is meticulously prepared by our skilled technicians using precision cutting, mounting, polishing, and etching techniques. State-of-the-art optical microscopy and image analysis software are employed to deliver accurate and detailed microstructural insights.

Fast Reporting and Reliable Service Across India

We provide a comprehensive microstructure analysis report-including photomicrographs, interpretations, and actionable recommendations-within one week. Our services are available offline throughout India, ensuring timely and consistent support for your metallurgical testing needs.

FAQ's of Metallography Testing Services:

Q: How are metallographic samples prepared for microstructural testing?

A: Samples undergo a systematic process of precision cutting, mounting, polishing, and etching by skilled technicians. This meticulous preparation ensures the revealing of key microstructural features for accurate analysis.Q: What types of metals and alloys can be tested with your metallography services?

A: Our services cater to a broad range of metals and alloys, including ferrous and non-ferrous materials, as long as the sample can undergo standard metallographic preparation and analysis.Q: When can I expect to receive the detailed microstructure analysis report?

A: You will receive a comprehensive report-including photomicrographs, interpretations, and recommendations-within one week of sample receipt, ensuring a fast and reliable turnaround.Q: Where are your testing services available?

A: Our metallography testing services are accessible all over India, with the process conducted offline to accommodate sample integrity and detailed analyses.Q: What is included in the metallography analysis report?

A: The report features high-quality photomicrographs, grain size measurements, inclusion ratings, as well as expert interpretation and specific recommendations aligned with ASTM, IS, and ISO standards.Q: How does metallography testing benefit quality control and failure analysis?

A: By revealing microstructural characteristics, such as grain structure and inclusions, our analysis assists in understanding material properties, investigating failures, and ensuring compliance with quality standards.Q: Who performs the metallography testing, and what tools are used?

A: All analyses are conducted by experienced metallurgists and skilled technicians using advanced optical microscopes and image analysis software to guarantee reliable and detailed results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese