Digital Hardness Testing Services

Digital Hardness Testing Services Specification

- Service Type

- Digital Hardness Testing Services

- Testing Type

- Hardness Testing

- On-site Testing

- Available on Request

- Measurement Range

- Up to 1500 HV / 70 HRC

- Mode of Report

- Hard (Copy/Soft Copy)

- Surface Preparation

- Minimal required

- Operation Mode

- Digital (Automated Reading)

- Applications

- Metals, Alloys, Plastics, Rubber

- Location

- All Over India

- Hardness Scale

- Rockwell, Brinell, Vickers

- Accuracy

- ± 1%

- Service Duration

- 1-5 Days

About Digital Hardness Testing Services

Micro Digital Hardness Testing by SV Tech Engineering

SV Tech Engineering offers precise micro digital hardness testing for a wide range of applications. This method is suitable for both new construction and in-service components, ensuring flexibility in testing.

Our portable equipment enables convenient on-site testing with quick and accurate results, suitable for various materials.

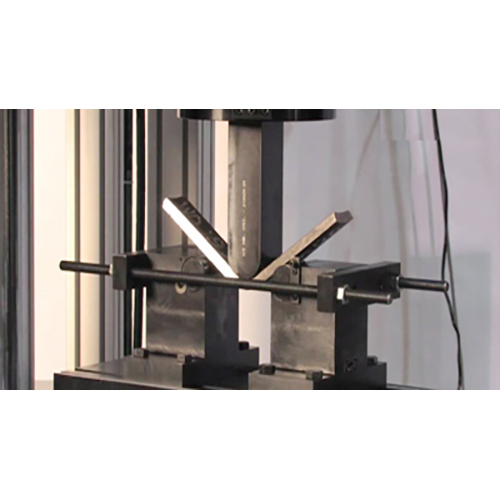

Hardness testing is essential for verifying the heat treatment of a part and determining if a material has the properties necessary for its intended use.

Hardness refers to a material's ability to resist plastic deformation, typically by penetration. It can also indicate resistance to bending, scratching, abrasion, or cutting.

Hardness values are measured by either the depth of indenter penetration or the size of the resulting indentation.

SV Tech Engineering ensures reliable hardness testing solutions for optimal material performance and durability.

Precision Testing with Digital Efficiency

Utilizing the latest digital technology, our hardness testing services provide rapid and precise measurement results while ensuring minimal disruption to your workflow. Automated readings eliminate human errors, guaranteeing reliability for quality assurance, research, and production applications.

Versatile Material Applications

Our expertise spans a wide range of materials, including metals, alloys, plastics, and rubber. Whether you are in manufacturing, automotive, or engineering sectors, our testing methods cater to diverse needs and industry standards, ensuring tailored solutions to your specific requirements.

Flexible and Accessible Service Nationwide

We offer nationwide coverage throughout India, including on-site testing upon request. Our streamlined process ensures quick turnaround times between 1 to 5 days, making our services ideal for urgent and routine testing requirements alike.

FAQ's of Digital Hardness Testing Services:

Q: How is digital hardness testing performed for different materials?

A: Digital hardness testing is conducted using advanced equipment that applies a controlled force to the sample and automatically measures hardness on scales such as Rockwell, Brinell, or Vickers. The process can accommodate metals, alloys, plastics, and rubber with minimal surface preparation.Q: What are the benefits of choosing digital hardness testing over manual methods?

A: Digital hardness testing offers higher accuracy (1%), automated data capture, and faster results. It reduces human error, streamlines reporting, and provides consistent results suitable for quality control, production, and research environments.Q: When is on-site digital hardness testing available?

A: On-site digital hardness testing services are provided across India and can be arranged upon request. This option is especially valuable for clients requiring testing at their own facility without sample transportation.Q: Where can I receive the test results and in which format?

A: You can obtain the test results throughout India, and reports are available in both hard copy and soft copy formats according to your preference, ensuring optinum accessibility and record keeping.Q: What is the process and timeline for digital hardness testing services?

A: Once a service request is received, our team schedules the testing (either at our lab or on-site), carries out the evaluation, and prepares comprehensive reports. The entire process generally takes 1 to 5 days based on sample quantity and location.Q: Can digital hardness testing services be used for all surface types?

A: Our testing service requires only minimal surface preparation, making it suitable for a wide range of surface finishes. This versatility allows us to effectively test raw materials, semi-finished, or finished products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese