Tensile Testing Services

About Tensile Testing Services

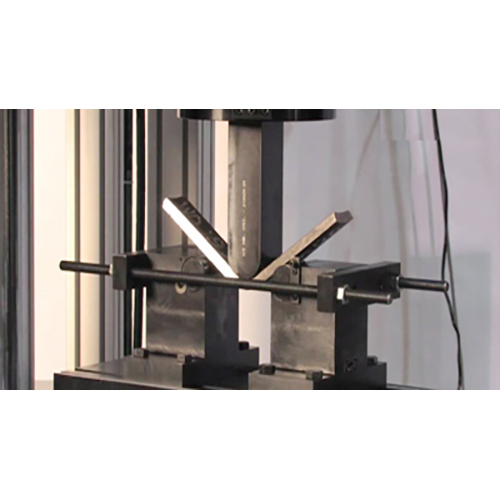

Testing on Universal Testing Machines (UTM)

About the Test:

The tensile test is conducted on various materials such as:

- Plates, pipes, bars

- Wires and thin foils

- Fine wires/foils with graphical representation

- TMT/TOR steel bars

Key Parameters Measured:

- Yield Stress: The stress at which a material starts to deform plastically.

- Ultimate Tensile Stress (UTS): The maximum stress a material can withstand without fracture.

- Elongation: Indicates the material's ductility.

- Stress-Strain Graph: Illustrates the material's behavior under load.

- Young's Modulus: Measures the material's stiffness.

- Proof Stress: Used for materials without a clear yield point, commonly measured at 0.2% deformation.

Key Concepts:

- Ductility: A material's ability to undergo plastic deformation before breaking, often expressed as % elongation.

- Malleability: A material's ability to deform under compressive stress, though not directly measured in tensile testing. An estimate can be derived from % reduction in the cross-sectional area.

Equipment Used:

- Universal Testing Machine (UTM)

This test is crucial for determining a material's strength, ductility, resilience, and toughness, ensuring it meets the required performance standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese