Impact -Izod Testing

Impact -Izod Testing Specification

- Measurement Range

- Up to 25 Joules

- Operating Temperature

- Room Temperature

- Pendulum Weight

- Up to 2 Kg

- Specimen Size

- 10mm x 10mm x 55mm

- Test Type

- Izod Impact Testing

- Display Type

- Analog / Digital

- Impact Velocity

- 3.5 m/s

- Mounting

- Table Top

- Application

- Plastic, Metal, and Composite Material Testing

About Impact -Izod Testing

SV Tech offers Impact Testing facilities in compliance with both ISO and American Standards (ASTM).

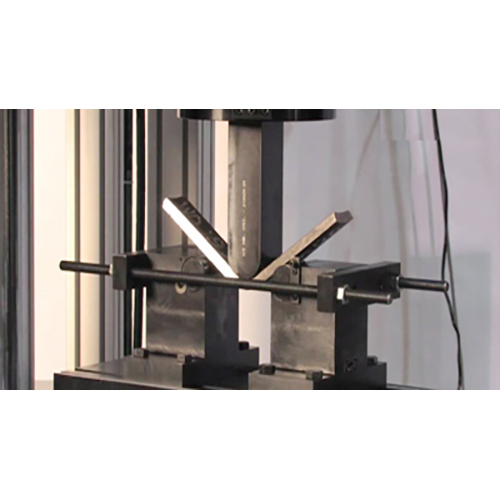

We conduct Izod and Charpy Impact Tests using IS, BS, and ISO-certified machines to evaluate a material's ability to absorb energy under sudden impact conditions. In certain cases, ductile materials may exhibit brittle failure, which is characterized by low energy absorption. The key factors contributing to such failures include:

- A tri-axial state of stress

- Low temperatures

- High strain rate or rapid loading

The Charpy Impact Test is widely used in the United States, while the Izod Impact Test is more common in Great Britain. Both testing methods follow standardized procedures as per ASTM E 23, ensuring accurate assessment of material toughness and resistance to impact failure.

What is Izod Impact Testing?

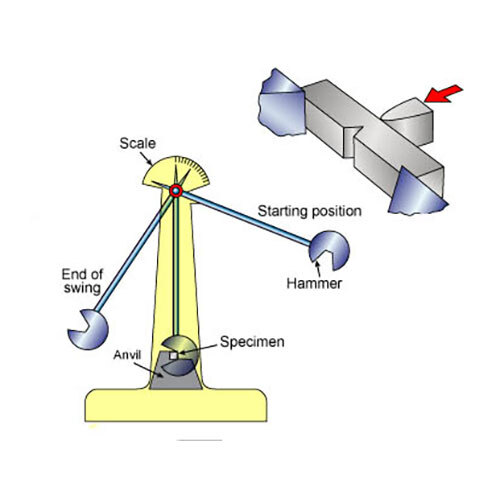

Izod Impact Testing is a standardized test method that determines a material's resistance to impact. It involves striking a notched specimen with a pendulum and measuring the energy absorbed until fracture. This procedure is crucial for assessing the toughness and durability of materials used in various industrial sectors, particularly for plastics, metals, and composites.

Wide Application Across Industries

Our testing services cater to a range of industries where safety and quality are paramount. Whether you are producing plastic components, metal parts, or composite materials, Izod impact testing helps evaluate how your materials perform under sudden force, aiding in design verification and compliance with international standards.

FAQ's of Impact -Izod Testing:

Q: How is the Izod Impact Test conducted using your service?

A: The Izod Impact Test is conducted by preparing a 10mm x 10mm x 55mm specimen, which is notched and then mounted vertically in the device. A pendulum of up to 2 kg is released to strike the specimen at 3.5 m/s. The energy absorbed during fracture is measured, providing a quantitative assessment of material toughness.Q: What types of materials can be tested with your Izod Impact Testing service?

A: Our Izod Impact Testing service is suitable for plastics, metals, and composite materials. This versatility makes it valuable in various industries including automotive, aerospace, manufacturing, and research institutes.Q: When should Izod impact testing be performed, and why is it important?

A: Izod impact testing should be performed during material selection, product development, quality control, and failure analysis. It is important because it helps predict how materials will behave under impact loads, ensuring safety and performance in their final applications.Q: Where is your Izod Impact Testing service available?

A: Our Izod Impact Testing service is available throughout India. Samples can be sent to our laboratory for testing, and results are provided along with detailed reports to support your quality assurance needs.Q: What is the process for submitting specimens for Izod testing?

A: Clients need to supply specimens measuring 10mm x 10mm x 55mm. Upon receiving your samples, we prepare and test them according to standardized protocols and deliver results via analog or digital readouts, depending on your preference.Q: What are the key benefits of using your Izod Impact Testing service?

A: Key benefits include reliable evaluation of material toughness, assistance in product design validation, compliance with industry standards, and detailed reporting. This helps you make informed decisions about material suitability and product safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese