About

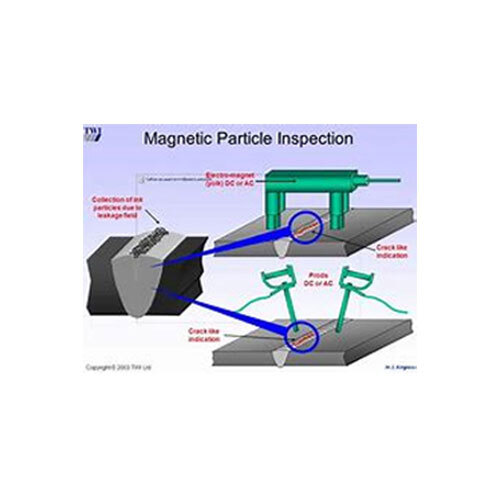

This method is used to detect surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and their alloys. The process involves introducing a magnetic field into the component.

The purpose of this test is to identify small defects before they develop into larger issues that could lead to serious failures. In magnetic particle inspection, a magnetic field is induced using a magnet or electrical current. Fine iron particles are then applied to the object's surface, aligning along the magnetic field lines. If a defect or crack is present, the magnetic field is disrupted, causing the particles to cluster along the flaw's edges.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाईल number

Email

चौकशी पाठवा

चौकशी पाठवा

चौकशी पाठवा

चौकशी पाठवा English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese